10/11/2023

Acaba el proyecto SOILSENSE liderado por LENZ INSTRUMENTS en colaboración con IREC para el desarrollo de tecnologías fotónicas para la monitorización de partículas de polvo en dispositivos fotovoltaicos.

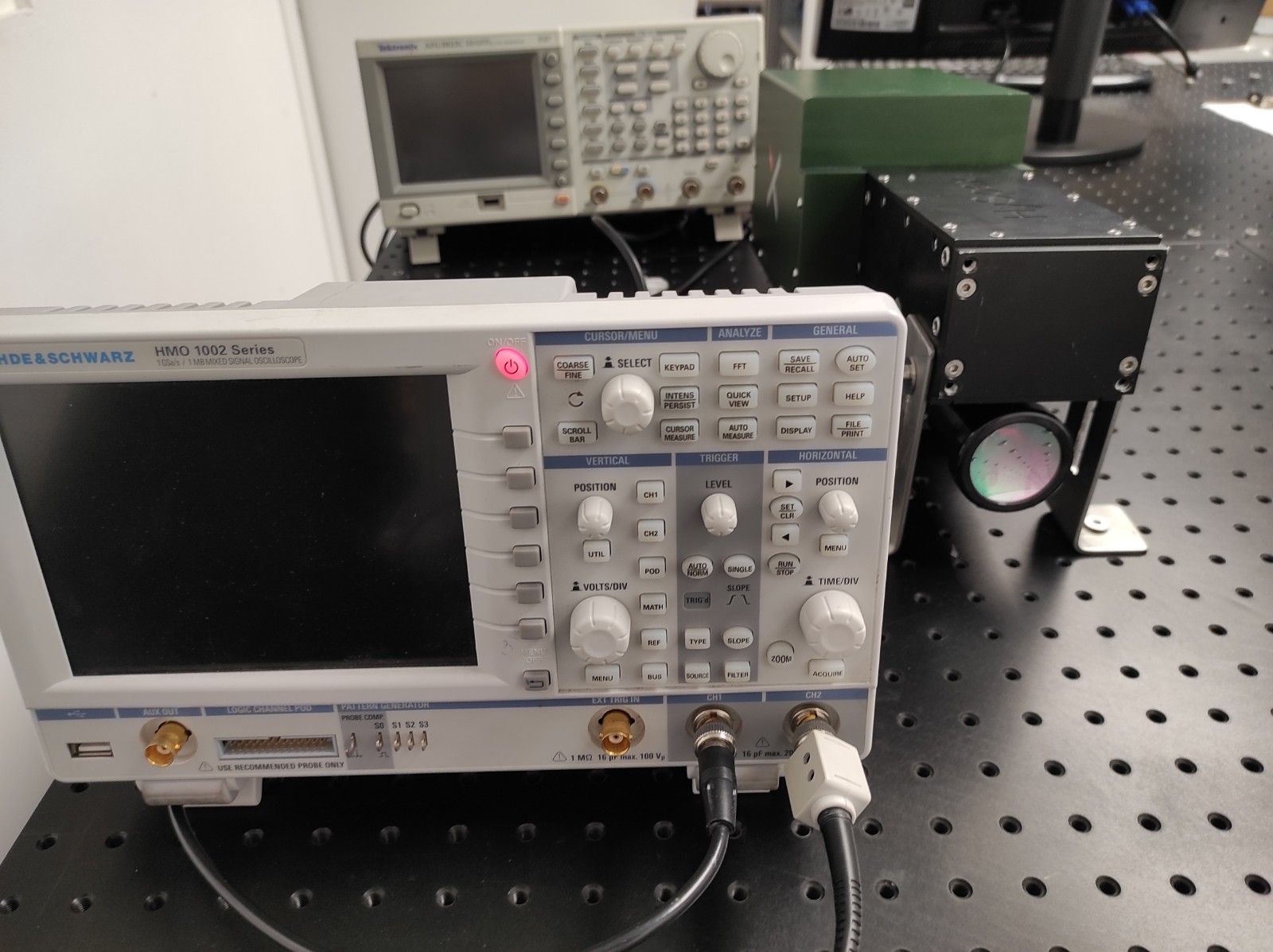

Después de año y medio de ejecución, acaba el proyecto SOILSENSE en el que LENZ INSTRUMENTS ha colaborado junto a Ia Fundación Instituto de Investigació de la Energia de Cataluña (IREC). Durante el marco de este proyecto, IREC ha desarrollado un sistema para la caracterización óptica de partículas de polvo así como una metodología para la medida de sus propiedades. Por su parte, LENZ INSTRUMENTS ha desarrollado algoritmos de Inteligencia Artificial que predicen la transmitancia de la capa de polvo y su efecto sobre la eficiencia de los paneles solares. Este proyecto INNOTEC ha sido financiado por ACCIÓ.

09/05/2023

Nueva Solución para la Inspección de Polivinil Butiral (PVB) en vidrio laminado

En el marco del proyecto colaborativo europeo SUNRISE (grant Agreement nº958243), LENZ INSTRUMENTS ha desarrollado una solución novedosa para la inspección de Polivinil Butiral (PVB) en vidrio laminado.

05/05/2023

El proyecto europeo ICEBERG afronta su último año de actividad con todos los casos prácticos en marcha

Bilbao, 5 de mayo de 2023. El Proyecto ICEBERG liderado por TECNALIA Research & Innovation y en el que participan 35 organizaciones públicas y privadas de diez países europeos, afronta su último año de trabajo con avances importantes en el reciclaje de los materiales de construcción, nuevas publicaciones científicas y patentes en marcha.

20/12/2022

IN4CIS – INSPECCIÓN DE DISPOSITIVOS FOTOVOLTAICOS DE 3ª GENERACIÓN

En el marco del proyecto IN4CIS, Lenz Instruments ha desarrollado un sistema para la inspección de dispositivos fotovoltaicos de 3ª generación de hasta 30×30 milímetros de tamaño. El sistema integra un cabezal multi-sensor compuesto por una sonda Raman y una sonda de fotoluminiscencia.

17/11/2022

HAM BrAIn – Inteligencia Artificial aplicada al proceso de elaboración del jamón curado

HAM BrAInTM es un software de Inteligencia Artificial para modelar, optimizar y controlar el proceso de elaboración del jamón curado. El software utiliza datos estadísticos del proceso tales como: peso, grasa, mermas y sal, que son determinados pieza a pieza, por el escáner de inducción magnética HAM-Inspector II.

12/05/2022

LENZ INSTRUMENTS colaborará junto al grupo de Materials i Sistemes d’Energia Solar de IREC (Fundación Instituto de Investigació de la Energia de Cataluña) para desarrollar metodologías que permitan monitorizar la presencia de polvo en instalaciones fotovoltaicas.

La colaboración se realizará en el marco de un proyecto INNOTEC financiado por ACCIÓ llamado SOILSENSE que tiene como objetivo el estudio de tecnologías fotónicas para la monitorización de partículas de polvo en dispositivos fotovoltaicos. Durante este proyecto se desarrollarán también modelos de tratamiento de datos basados en algoritmos inteligentes para predecir, a partir de la respuesta de este sistema sensor, el impacto que tiene el polvo sobre el rendimiento energético de la instalación. El proyecto que empieza ahora finalizará en noviembre del 2023.

05/04/2022

FOTO-CER, desarrollo de dispositivos fotovoltaicos transparentes integrados en elementos cerámicos de construcción

El proyecto FOTO-CER tiene por objetivo desarrollar dispostivos fotovoltaicos transparentes para su integrción en materiales cerámicos (baldosas), para su aplicación en fachadas, manteniendo sus cualidades estéticas

26/09/2021

Línea Piloto para la Separación y Reciclaje de Residuos de Construcción y Demolición

Estamos trabajando en el desarrollo de una línea piloto para clasificar fracciones cerámicas mixtas de residuos de construcción y demolición. La línea piloto está diseñada para procesar hasta 1 tonelada por hora de material de entrada y tiene como objetivo clasificarlo en tres corrientes principales: fracción gris (hormigón), fracción roja (fragmentos de ladrillo) y otros materiales, incluido el yeso.

09/09/2021

Sistema óptico para la inspección de módulos fotovoltaicos de 3ª generación

Lenz Instruments ha completado el desarrollo en fase de demostrador, de un novedoso sistema de inspección automatizado para analizar automáticamente los módulos fotovoltaicos de capa fina. El sistema integra un cabezal óptico, encargado de conducir la luz hasta el módulo fotovoltaico a inspeccionar, recoge su emisión óptica y la guía hasta diferentes módulos espectroscópicos para su análisis. Mediante técnicas avanzadas de procesamiento de datos, esta información espectral se puede utilizar para evaluar la calidad y eficiencia de los materiales de película delgada obtenidos durante el proceso de fabricación de los dispositivos. La detección temprana de defectos de fabricación es de suma importancia para (1) identificar errores de fabricación e implementar acciones tempranas; (2) maximizar el rendimiento del proceso de fabricación; (3) asegurar la calidad y la fiabilidad de los módulos; y (4) minimizar la generación de residuos durante el proceso de fabricación.

30/06/2021

SUNRISE – SOLUCIÓN PARA LA SEPARACIÓN Y RECICLAJE DEL POLIVINIL BUTIRAL (PVB)

El pasado 1 de junio de 2021 se ha iniciado el proyecto europeo SUNRISE, en el que se plantea el desarrollo de nuevas soluciones para la separación y reciclaje del polivinil butiral (PVB) procedente de vidrio laminado. El proyecto está financiado por el programa marco de investigación e innovación de la Unión Europea Horizonte 2020 (grant agreement nº 958243).