01/07/2020

Soluciones Avanzadas para la Separación de materiales de construcción al final de su vida útil (EBM)

En junio de 2020 comenzó oficialmente el Proyecto Europeo ICEBERG. El proyecto tiene como objetivo desarrollar y demostrar soluciones circulares, inteligentes y rentables para la recuperación de materias primas de construcción secundarias a lo largo de toda la cadena de valor circular: desde materiales de construcción al final de su vida útil (EBM) hasta nuevos productos de construcción preparados para circularidad. Esto se llevará a cabo a través de 6 casos de estudio, que representan globalmente más del 85% en peso del entorno construido europeo.

15/06/2020

LENZ INSTRUMENTS INICIA SUS ACTIVIDADES TÉCNICAS EN EL MARCO DEL PROYECTO IN4CIS

En el marco del proyecto de investigación Europeo In4CIS, Lenz Instruments ha iniciado sus tareas de diseño del sistema de inspección óptico para dispositivos fotovoltaicos de tercera generación basados en tecnología CIGS.

10/01/2020

NUEVAS METODOLOGÍAS ÓPTICAS PARA EL CONTROL EN LÍNEA DE PROCESOS DE FABRICACIÓN DE CÉLULAS SOLARES DE ALTA EFICIENCIA BASADAS EN CIGS

El proyecto de investigación Europeo In4CIS comenzó el pasado mes de septiembre de 2019, en el marco del programa europeo SOLAR-ERA.NET Cofund 2.

29/10/2019

Determinación de grasa intramuscular en carne de cerdo mediante análisis no destructivo NIRS.

El martes 5 de Noviembre, se celebra el Palau Firal de Manresa una jornada técnica organizada por IRTA en colaboración con Lenz Instruments y otras empresas del sector agrícola. La jornada tratará sobre la mejora de un sistema de producción porcina basado en el Porc de Palou. Nuestro CEO Jacobo Álvarez, presentará los resultados obtenidos con una sonda NIR específicamente diseñada para determinar el contenido de grasa intramuscular en carne de cerdo.

30/09/2019

HAM Inspector II – Reducción de sal en jamón curado

Cada año nuestros analizadores en línea para la determinación de peso, grasa y sal, clasifican millones de piezas (paletas y jamones) con el objetivo de aumentar los rendimientos de producción y mejorar la calidad del producto. Nuestros equipos permiten implementar estrategias de control para optimizar la etapa de salado y reducir de manera significativa las mermas y las variaciones en el contenido final de sal.

03/05/2018

Lenz Instruments colabora con la empresa National Instruments en la publicación del caso de estudio Shreddersort

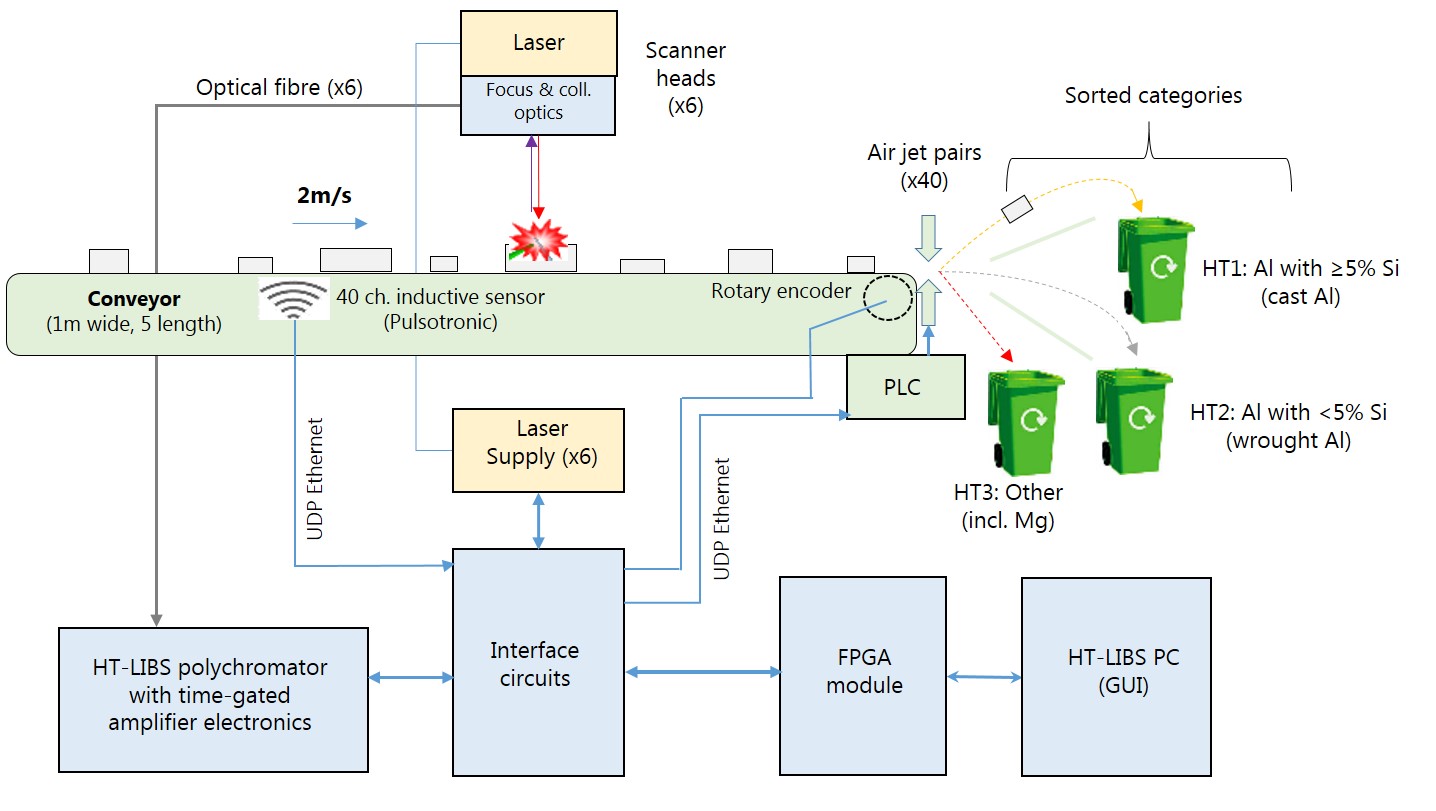

Shreddersort: Control de una planta de separación de metales mediante espectroscopía LIBS para la industria del reciclaje. El Reto:

Sobre una cinta transportadora a 2m/s, se pretende desarrollar un sistema que controle una línea de separación de residuos metálicos por detección y soplado, y que sincronice: (1) la detección por sensores inductivos de la posición de cada fragmento, (2) el disparo de un láser pulsado; (2) la adquisición del espectro de emisión óptica del plasma generado por los pulsos; y (3) la activación de las válvulas de soplado.

03/04/2018

LENZ estará presente en la próxima edición de la exposición FoodTech, del 8 al 11 de mayo 2018

Lenz Instruments asistirá a la sala TECNO CÁRNICA de la exposición FoodTech (Stand A-270), que se organizará en Barcelona del 8 al 11 de mayo. La feria comercial FoodTech se centra en la tecnología de los alimentos y es una de las más prestigiosas del sector. Con más de 37,000 visitantes profesionales de 115 países diferentes, FoodTech cuenta con la asistencia de 660 marcas comerciales de compañías locales e internacionales. Tecno Cárnica – la sala de exposiciones enfocada en maquinaria, tecnología, equipos y suministros para el sector de procesado de carne juega un papel clave en la feria, que representa más del 50% de la actividad de la Feria.

25/07/2016

Nuevos sistemas industriales de clasificación y separación basados en espectroscopía làser (LIBS), espectrocopía de inducción magnética y visión artificial para el reciclaje de fragmentos metálicos no férricos.

El consorcio de SHREDDERSORT está completando la construcción de tres sistemas individuales de clasificación y separación para el reciclaje de fragmentos metálicos provenientes de la industria del automóvil. Los tres sistemas de clasificación son:

27/04/2016

ShredderSort: Lenz instruments colabora en el desarrollo de una planta piloto para la separación de metales no-férricos

Dentro de la industria del reciclaje, existe un interés creciente por nuevas tecnologías que permitan la recuperación de metales a partir de residuos obtenidos de vehículos al final de su vida útil, así como otras fuentes de residuos industriales o urbanos. Las tecnologías actuales, no permiten la separación efectiva de diversos metales no férricos, y presentan limitaciones en términos de rendimiento y coste. En colaboración con otros socios industriales, Lenz Instruments ha desarrollado una planta piloto que permite la separación de residuos metálicos no-férricos en tres fracciones, en función de su composición química. El sistema desarrollado combina una matriz de sensores electromagnéticos y ópticos, que permiten determinar la composición de cada fragmento de residuo en tan sólo una milésima de segundo. El sistema de control de la planta procesa esta información en tiempo real, a la vez que regula el accionamiento de una matriz de válvulas neumáticas que separan cada fragmento en diferentes fracciones mediante soplado direccional.