Recycling sector

In the frame of two collaborative European Research projects, we are developing innovative recycling processes for the revalorization of end-of-life building materials and laminated glass waste.

ICEBERG – Innovative Circular Economy Based solutions demonstrating the Efficient recovery of valuable material Resources from the Generation of representative End-of-Life building materials

ICEBERG aims to design, develop, demonstrate and validate advanced technologies for the production of high-purity secondary raw materials through 6 circular case studies across Europe, covering circularity of wood, concrete, mixed aggregate, plasterboard, glass, polymeric insulating foams, and inorganic superinsulation materials. ICEBERG will develop novel technologies for the recovery of EBM, which include: HyperSpectral Imaging (HSI), machine-learning software, and robotic manipulators to increase sorting efficiency of mixed aggregates; An integrated crushing, sorting, and cleaning optimized system and fast pyrolysis and purification processes for wood fractions; Thermal attrition mobile unit integrated with LIBS and carbonation for concrete; Hydrocyclone combined with HSI sorting and acid purification to increase the purity of recycled plasterboard; A combined process of purification and solvolysis for polymeric insulating foams; Advanced hydrothermal and supercritical-based processing of glass and silica-containing waste.

Know more at: Iceberg

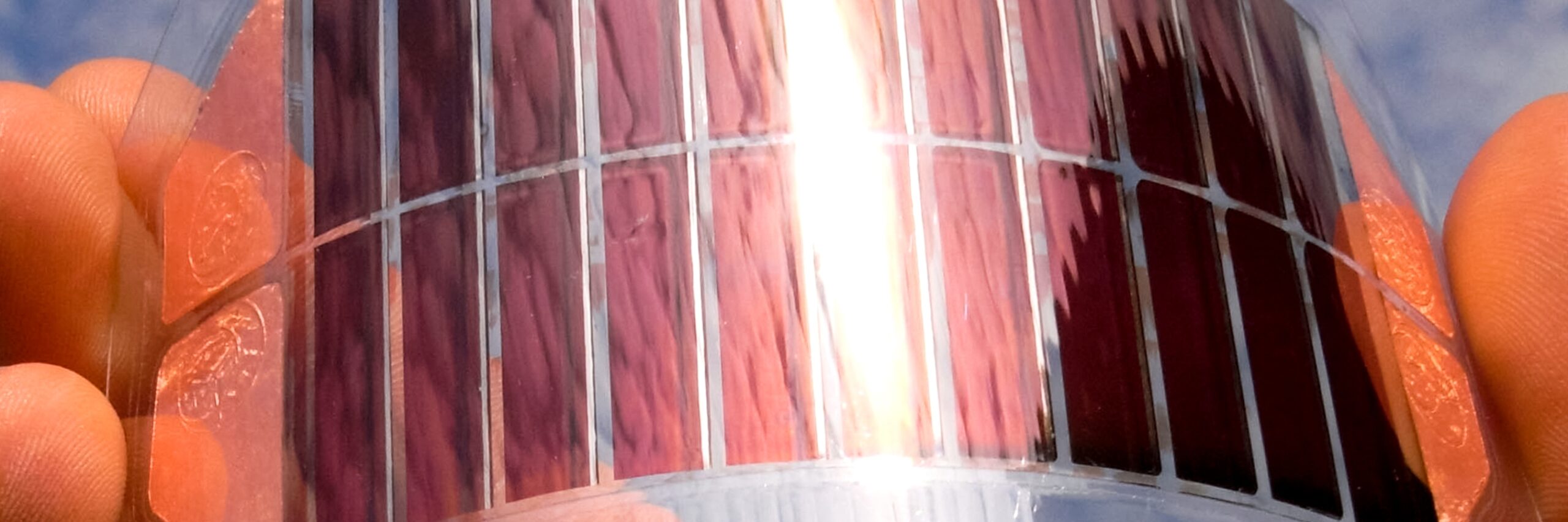

SUNRISE – MultiSensor sorting tools in a circular economy approach for the efficient recycling of PVB interlayer material in high-quality prodUcts from laminated glass coNstRuction and demolItion waStEs

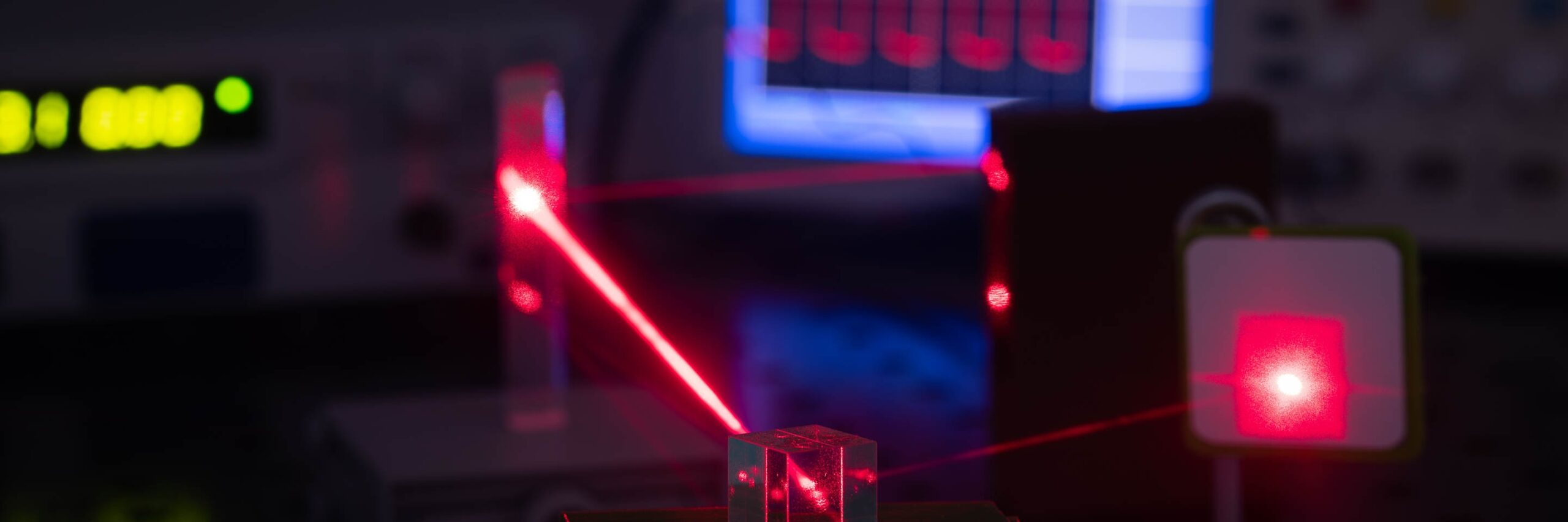

Laminated glass is obtained by bonding glass layers using a polymeric interlayer. Polyvinyl Butyral (PVB) is used as an interlayer in laminated glass and their use in construction components is growing, therefore the end-of-life should be addressed. SUNRISE will demonstrate within the current glass recycling business the application of an innovative optical multi-sensor sorting tool based on industrial in-line techniques (Raman, IRS, Fluorescence and Optical Spectroscopy) and AI algorithms which will allow optimal classification of laminated glass according to composition and degradation. The success of SUNRISE will avoid PVB wastes of more than 125.000 tons, representing significant economic, environmental, and social benefits.

Know more at: Sunrise