Download PDF

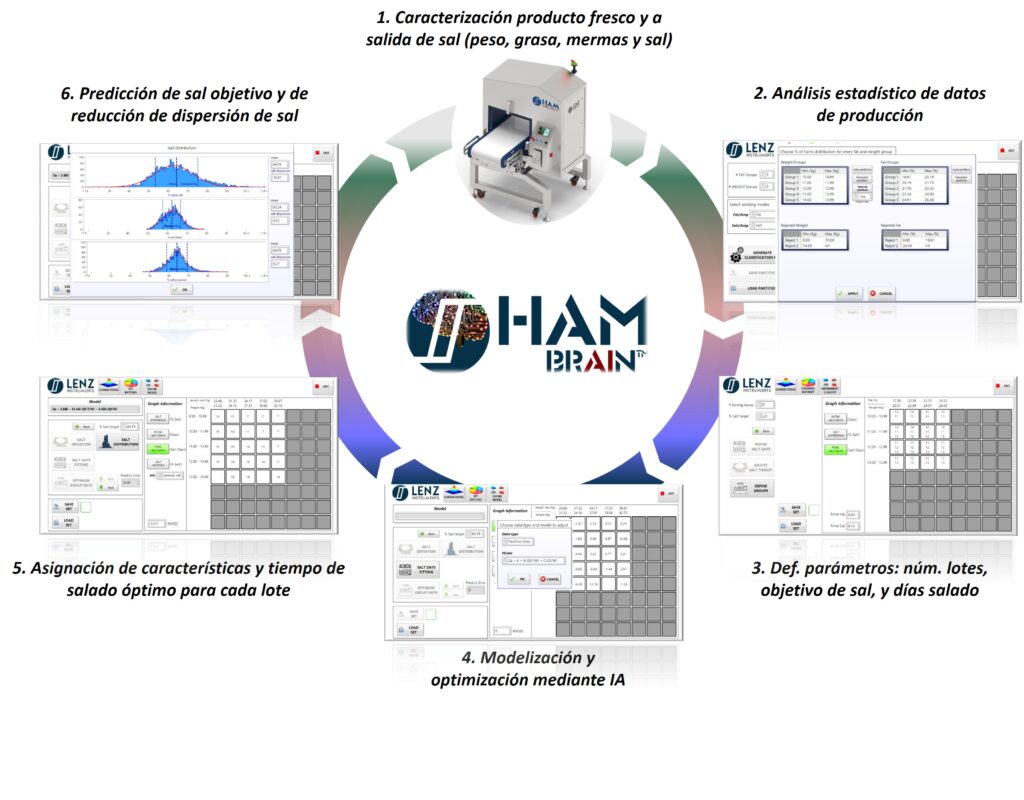

HAM BrAIn™ is an Artificial Intelligence software to model, optimize and control the cured ham production process automatically. The software uses statistical process data determined piece by piece by the HAM Inspector II magnetic induction scanner. The control strategy is based on the measurement of weight and fat at reception and on the measurement of shrinkage and salt after the salting stage. The process is carried out in six stages:

- Phase I (Characterization): Characterization of the production process. Determination of weight, fat, shrinkage and salt.

- Phase II (Statistical Analysis): Statistical analysis of production data.

- Phase III (Salt target): Definition of target salt %, total number of salting groups and salting days.

- Phase IV (Modeling): Modeling and optimization.

- Phase V (Classification): HAM BrAIn™ optimizes sorting to achieve the salt target with minimal dispersion.

- Phase VI (Feedback): HAM BrAIn™ continues to learn from the process to continuously readjust itself.