The HAM Inspector II™ has been designed to be a versatile tool for dry-cured meat processors that wants to improve their production processes through a more efficient classification of the raw meat, and by monitoring the salting stage.In deboning rooms, the equipment allows to improve the standardization of batches by a more reliable and accurate determination of the fat content in the raw meat.

HAM Inspector™ employs a contactless inspection (patented) developed in collaboration with IRTA (Research and Technology, Food and Agriculture) and SSICA (Experimental Station for the Food Preserving Industry). The measurement is based on the different response of fat and lean tissues to a low intensity variable magnetic field.

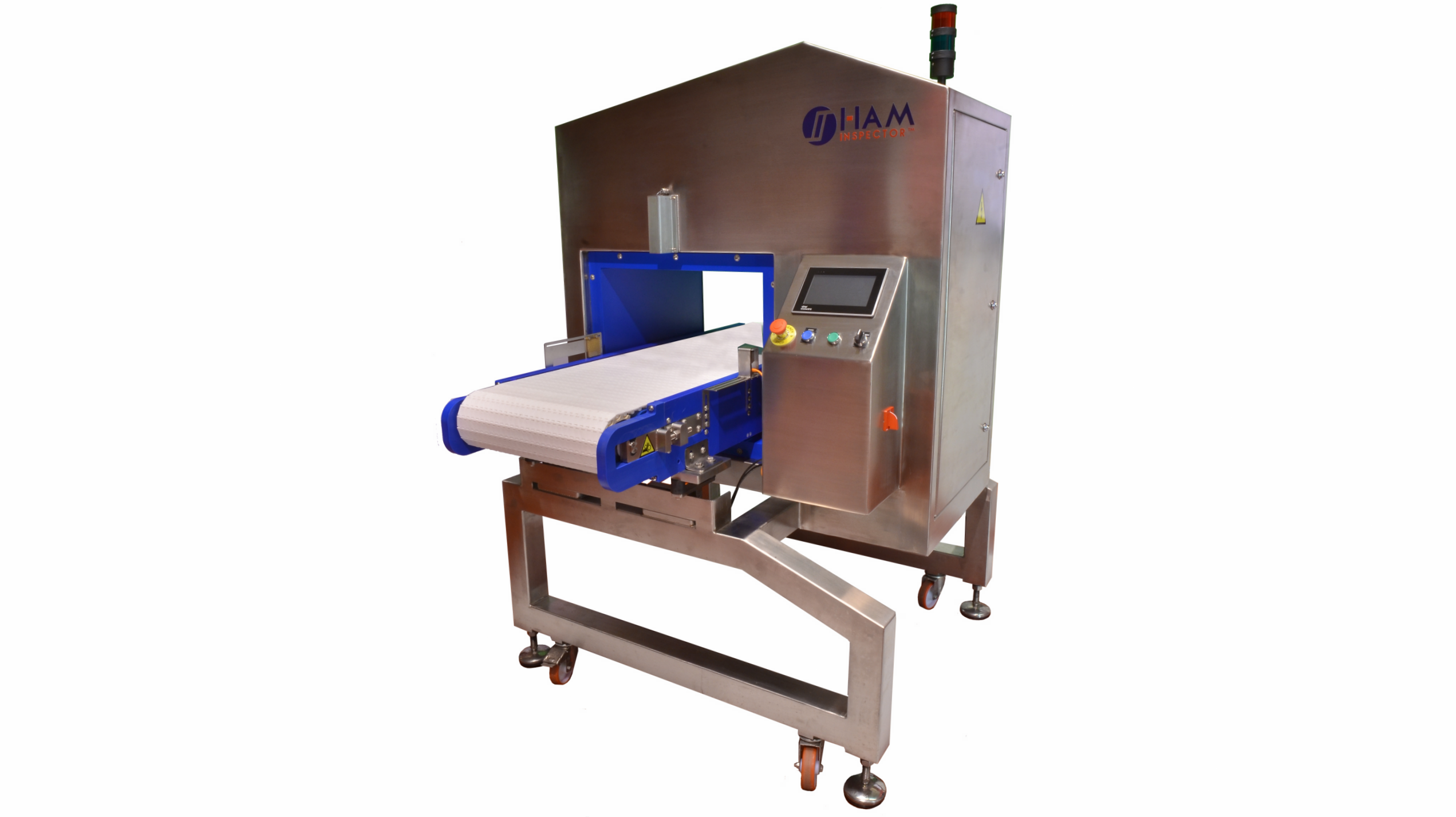

The equipment is a compact system that can be easily integrated in a processing line for the continuous analysis of the meat production, with a throughput of up to 1200 pieces/hour. The machine includes correlation models to automatically calculate the fat content of the fresh meat, with an accuracy better than 1.1% (RMSE) and the salt content with an accuracy better than RMSE<0.1%.