10/02/2026

HAM BrAIn – Artificial Intelligence applied to the cured ham manufacturing process

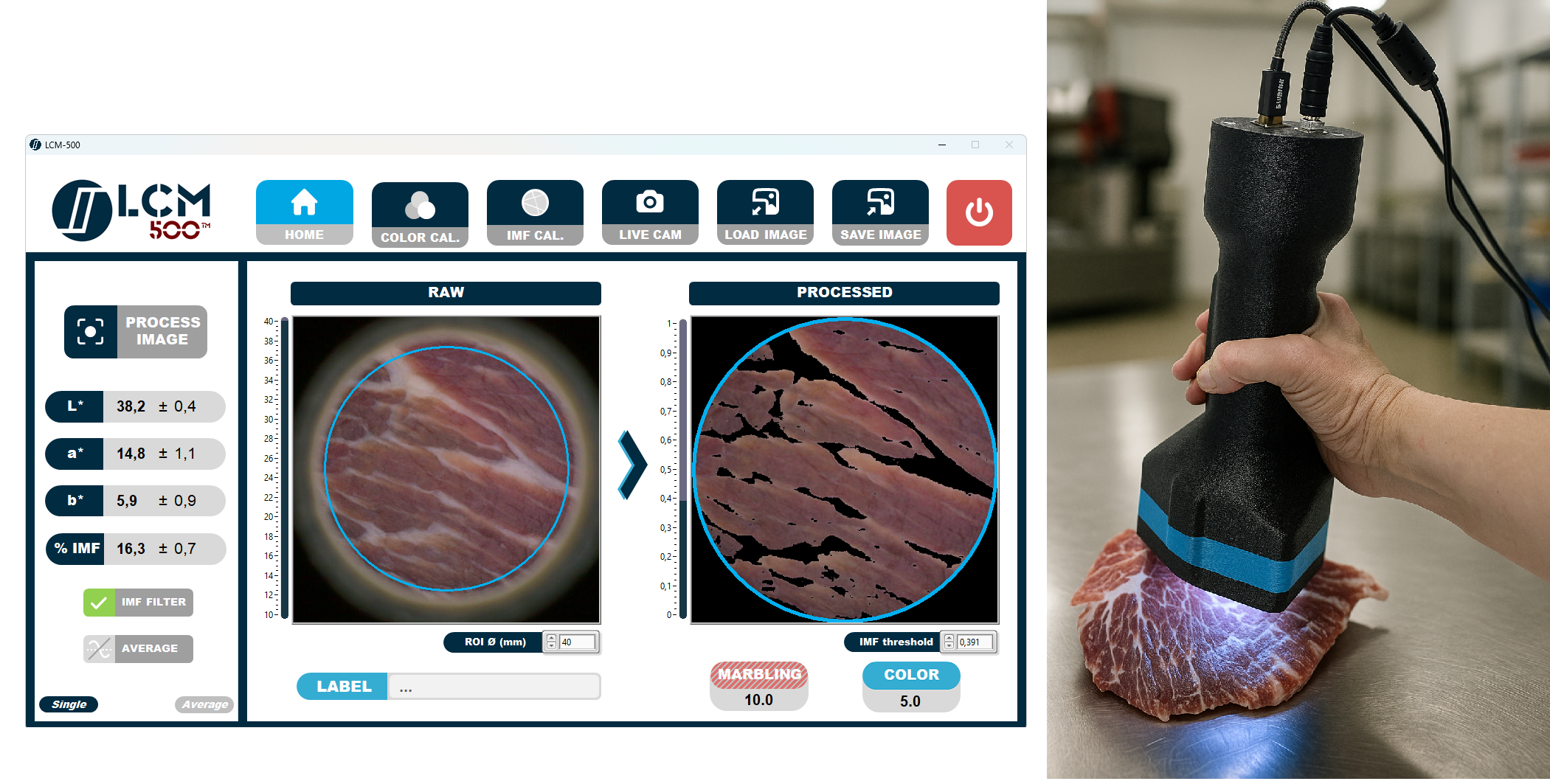

HAM BrAInTM is an Artificial Intelligence software for modeling, optimizing and controlling the cured ham production process. The software uses statistical process data such as weight, fat, shrinkage and salt, which are determined piece by piece by the HAM-Inspector II magnetic induction scanner.

10/02/2026

New Multisensor for In-Line Inspection of Incineration Residues

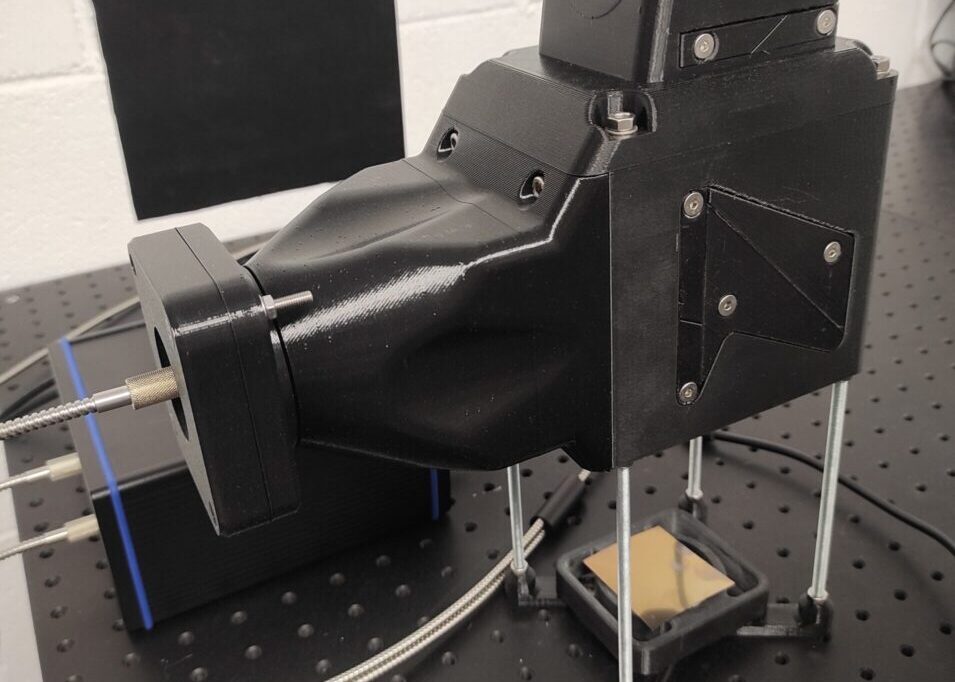

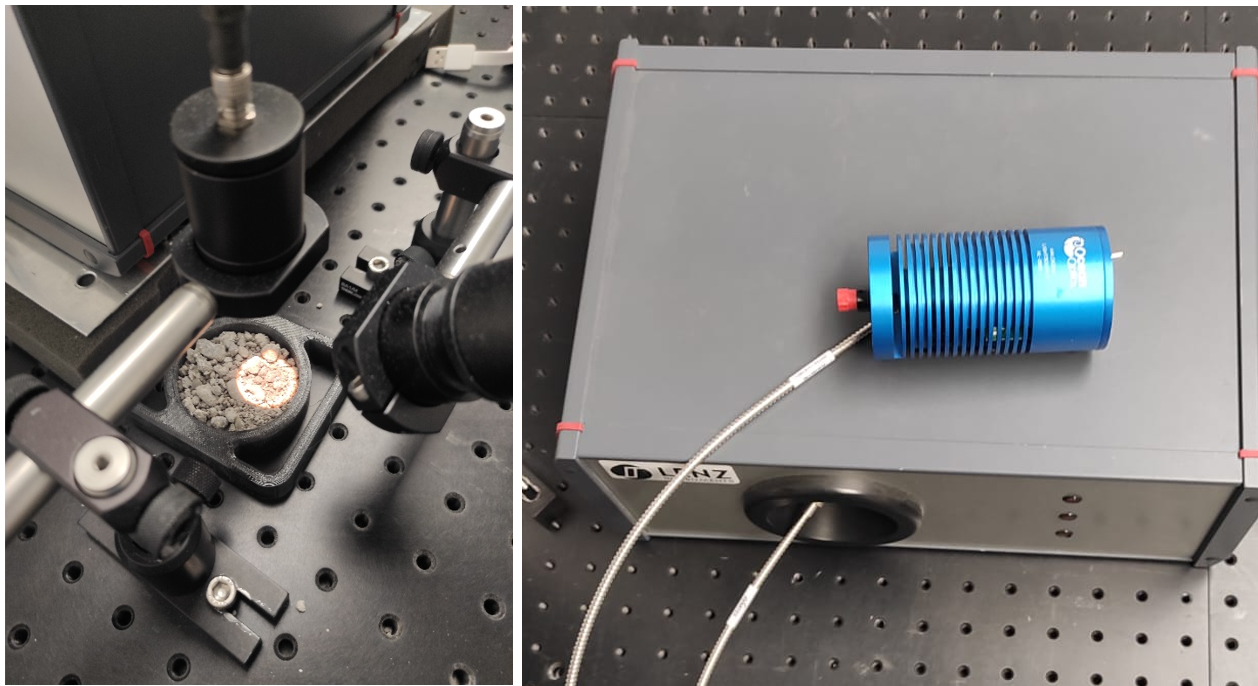

Within the framework of the ATRIC 4.0 project, LENZ INSTRUMENTS has developed an innovative multisensor system for the inspection of incineration slags. The multisensor is based on the combination of various custom-developed spectroscopic sensors and the application of advanced algorithms for processing spectral information using deep learning techniques.

10/02/2026

The SOILSENSE project led by LENZ INSTRUMENTS in collaboration with IREC for the development of photonic technologies for the monitoring of dust particles in photovoltaic devices has come to an end.

After a year and a half of execution, the SOILSENSE project in which LENZ INSTRUMENTS has collaborated with the Energy Research Institute of Catalonia Foundation (IREC) has come to an end. During this project, IREC has developed a system for the optical characterization of dust particles as well as a methodology for the measurement of their properties. LENZ INSTRUMENTS has developed Artificial Intelligence algorithms that predict the transmittance of the dust layer and its effect on the efficiency of solar panels. This INNOTEC project has been funded by ACCIÓ.

10/02/2026

New Methodology for Detecting Defects in Transparent Solar Cells

Conventional solar cells are based on the principle of generating electricity through light absorption. For this reason, technologies developed so far use highly absorbent materials to ensure optimal utilization of the solar spectrum. However, this characteristic poses a limitation for the integration of photovoltaics in applications such as architecture, where the opacity of traditional solar cells is incompatible with the required functional and aesthetic needs.

10/02/2026

Lenz Instruments develops a Demonstrator for the Inspection of Transparent Photovoltaic Devices

Within the framework of the FOTO-CER project, Lenz Instruments has developed, at a demonstrator prototype scale, an innovative inspection system for transparent photovoltaic devices. The system is based on the integration of multiple optical sensors and enables fully automated inspection of 30×30 cm² photovoltaic mini-modules.

10/02/2026

The FOTO-CER Project comes to an end

On December 31, 2024, the FOTO-CER research project, co-financed by CDTI under the MISSIONS Program, in which Lenz Instruments participates as a technology-based company, came to an end.

10/02/2026

ATRIC 4.0 – ATRIC 4.0 – Follow-up meeting in Madrid

On June 14, we had the opportunity to visit ACCIONA’s Construction Technology Center in Madrid, where a follow-up meeting for the ATRIC 4.0 project was held (Accelerating the Transition to a sustainable, digital, and circular Industry 4.0, with new process technologies, AI, and industrial symbiosis to maximize the valorization of combustion waste in the infrastructure sector and reduce CO₂ emissions).

10/02/2026

ATRIC 4.0 – challenge at the Industrial Efficiency Awards

The ATRIC 4.0 project, in which LENZ INSTRUMENTS participates, has been chosen as a challenge in the 2025 edition of the Industrial Efficiency Awards, organized by ISOVER with the support of ACCIONA.

10/02/2026

MARVEL: In the final stretch of our INNOWWIDE project

At Lenz Instruments, we are reaching the final stage of the MARVEL project, an initiative funded by the European Union through the INNOWWIDE programme, which promotes the internationalisation of European SMEs by means of market feasibility studies in strategic countries.

10/02/2026

Closure of the ATRIC 4.0 project

After more than three years of work, the ATRIC 4.0 project is coming to an end with important advances in digitalization and circularity applied to the industrial sector.