HAM BrAIn – Artificial Intelligence applied to the cured ham manufacturing process

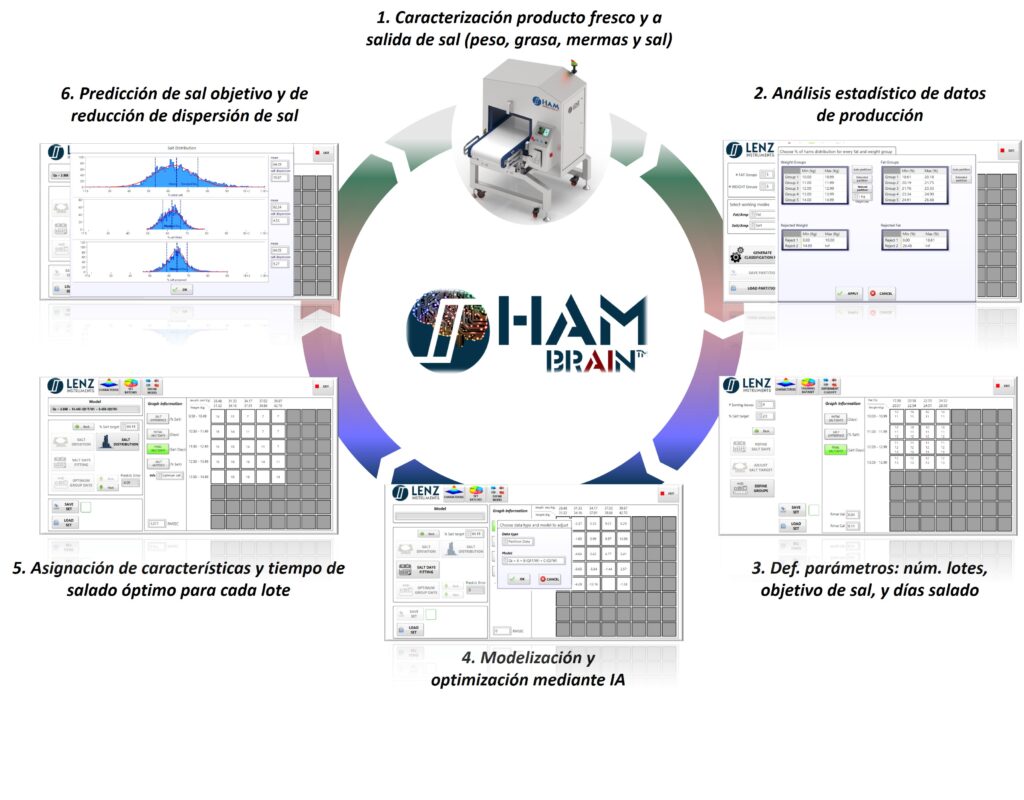

HAM BrAInTM is an Artificial Intelligence software for modeling, optimizing and controlling the cured ham production process. The software uses statistical process data such as weight, fat, shrinkage and salt, which are determined piece by piece by the HAM-Inspector II magnetic induction scanner.

The objective of this development is to apply Artificial Intelligence and Big Data techniques to optimize the cured ham production process automatically. The control strategy is based on the measurement of weight and fat at reception and on the measurement of shrinkage and salt after the salting stage. The process is carried out in 4 phases:

- Phase I (Characterization): Characterization of the production process. Determination of weight, fat, shrinkage and salt.

- Phase II (Salt target): Definition of the target % of salt and the total number of salting groups.

- Phase III (Classification): HAM BrAInTM optimizes sorting to achieve the salt target with minimum dispersion .

- Phase IV (Feedback): HAM BrAInTM continues to learn from the process to continuously readjust itself.

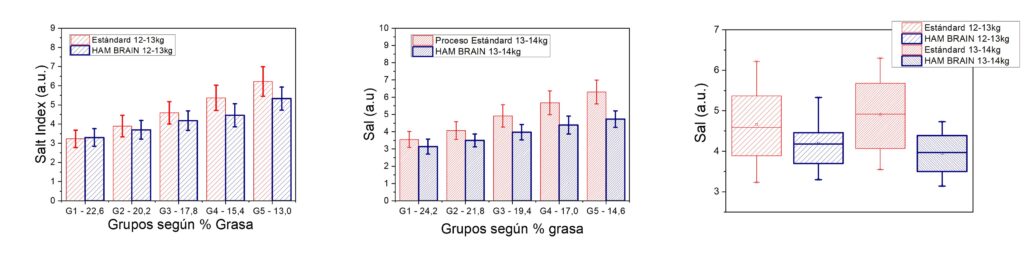

By applying this Artificial Intelligence tool in an industrial test with thousands of hams, it has been possible to reduce the dispersion of the final salt content by 50%. This reduction in salt dispersion has also made it possible to adjust the target salt values without compromising the food safety of the product.

Conclusions

- Total fat content and ham weight are the main factors affecting the variation in salt content and wastage in the production of cured ham.

- HAM Inspector II™ together with HAM BrAInTM Artificial Intelligence software, allows to automatically optimize and control the cured ham production process and to implement salt reduction strategies.

Collaborations

This work has been carried out between Lenz Instruments and Boadas 1880 at the Dehesa de Guijuelo plant (Montejo, Salamanca). The study aims to: a) automate the salting and curing process by characterizing the raw material, b) reduce salt variations in the final product and c) adjust the average salt content automatically.